Marginal gains make champions.

Every second is gold!

At the forefront of R&D

At the core of Rex product development is detailed and reliable test data, based on decades of experience with wax products and carefully selected, top-quality raw materials from the chemical industry.

Gold Liquid is once again a testament to this intense research and development work, as well as the waxing expertise that can only be found at Rex.

We are proud to add the Gold Liquid glide coating to the top-tier Rex product family.

Test Range

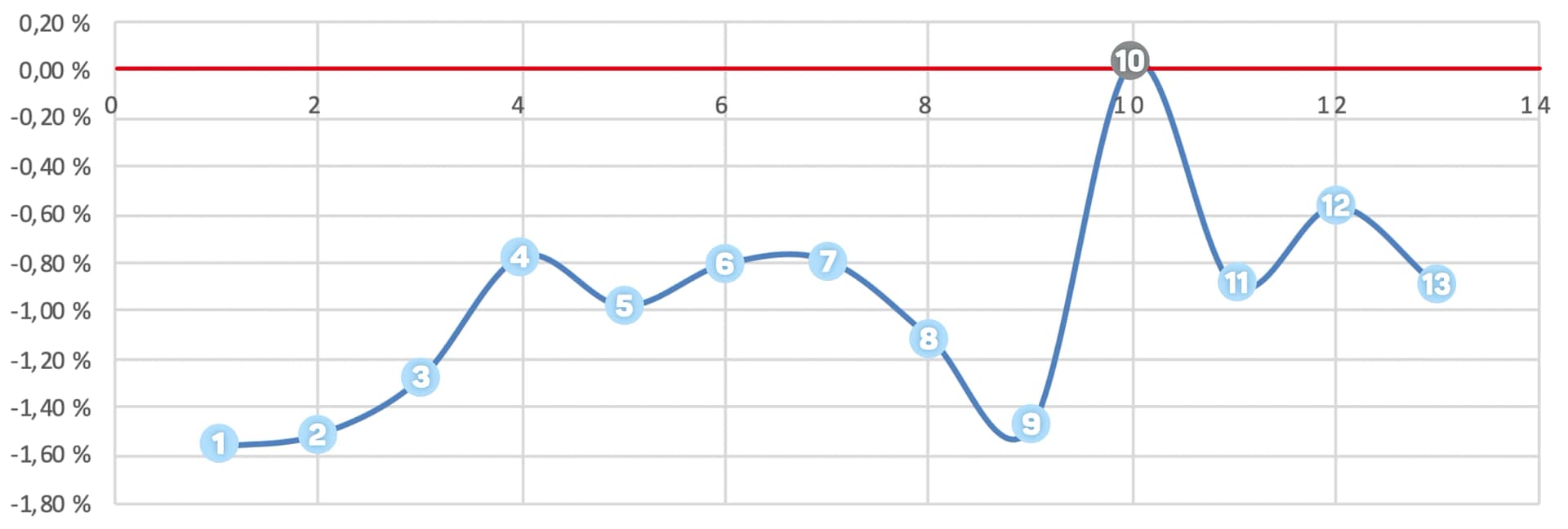

NF31 | 0,000%

NF31 + Gold Liquid | -0,971%

*test averages

Durability test

Test type: durability, speed test

Location: Lahti, Sports Center

Date: 16.1.2025

Operators: Juuso Liukkonen / Juho Korvenoja

Test Pack: Atomic

Snow type: natural/artificial

Snow age: old

Air temperature: +1,5°C

Snow temp., -5cm: -0,6°C

Snow humidity: 40-50

Test day data on Strava:

Test plan

We wanted to test the durability of Rex Gold Liquid, how quickly the improvements diminish, and whether there is any deterioration in glide compared to a control wax. The assumption is that the durability of liquid top coatings is worse than that of solid, iron-applied waxes and powders. Some liquid top coatings may also be very slippery for the first few hundred meters, but their glide deteriorates dramatically after that. This could even result in worse skis than without applying the coating.

Durability test

We prepared two pairs of calibrated glide test skis with the same waxes. The difference was that on one pair, we used Rex Gold Liquid as the coating, at that point still under the code name TK-501.

1st pair: SISU White Base + NF31 Green

2nd pair: SISU White Base + NF31 Green + Gold Liquid

The testing was conducted using a SkiSpeed meter, which measured the time taken for each test run. The test began with three glide tests, where both pairs of skis underwent glide testing. All the glide tests were performed by the same skier, ensuring that any variation between skiers did not affect the run times. After the glide tests, both pairs skied the same loop simultaneously. Following the ski loop, the glide tests were repeated, and this continued until approximately 25 kilometers of skiing had been completed.

Results and analysis

The ski waxed with Rex Gold Liquid was faster than the reference ski in all but one test run. The test results were consistent with previous tests. In durability tests conducted through skiing, Rex Gold Liquid consistently remained as fast or faster than the reference waxes.

Regarding the test results: We used measuring equipment to record the descent times and calculated the relative difference, which we use for analyzing the test results. In modern ski racing, glide tests are mostly conducted as paired runs, where the result is given as a difference in centimeters. When comparing paired runs to the timing method we used (often referred to as “gating”), a common rule of thumb is that 10 cm corresponds to a 0.1% difference. Differences below 20 cm / 0.2% are considered small. Differences between 20 cm and 60 cm (0.2%–0.6%) are clearly noticeable in glide when skiing with alternating ski pairs. Differences between 0.8% and 1.6% are significant, while differences greater than 1.6% are rarely seen when testing race waxes.

In practice, this means that Gold Liquid provides a clear advantage in a race situation. The lead gained in each descent accumulates into winning seconds!

Results

Application method test

We wanted to examine the best way to apply Rex Gold Liquid. Liquids are typically corked, applied with merino or fleece roto, brushed with a nylon brush, or simply spread without additional treatment. Based on previous tests, the assumption for Gold Liquid was that the best results would come from simple application without brushing or any further processing.

We tested 3 different application methods

1. Spray onto the ski, application with a fiber cloth.

2. Spray onto the ski, application with a fiber cloth. 5-minute drying time, followed by brushing with a nylon brush.

3. Spray onto the ski, application with a fiber cloth. 5-minute drying time, followed by merino roto brushing and finally brushing with a nylon brush.

Summary

The results show that application method #1 provided the best glide in every test conducted. The tests included not only cold conditions but also wet and zero-degree tests, confirming that this application method works across different weather conditions. In race tests, it was also found that the liquid should be applied to the ski surface only after any hand corking or pressure treatment. Devices with a rotor for hand corking do not provide enough grip on the treated ski surface.

Now available